Fabric tank

With a Flexilo fabric tank, your pellets are space-saving and cost-efficiently stored at the same time.

You can determine the set-up location yourself and do not need a separate storage room. We offer you the right design for every space and pellet requirement.

There are different fabric tank sizes from 499 kg to 12 tons storage capacity to choose from.

Information and tips for the planning of pellet heating systems with fabric tanks

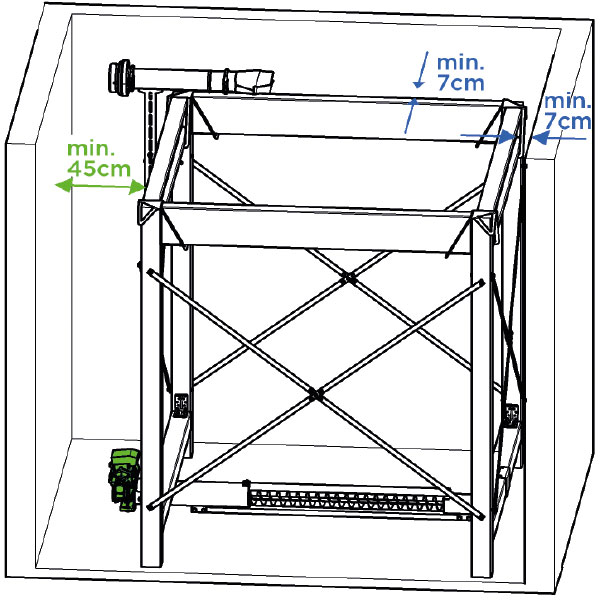

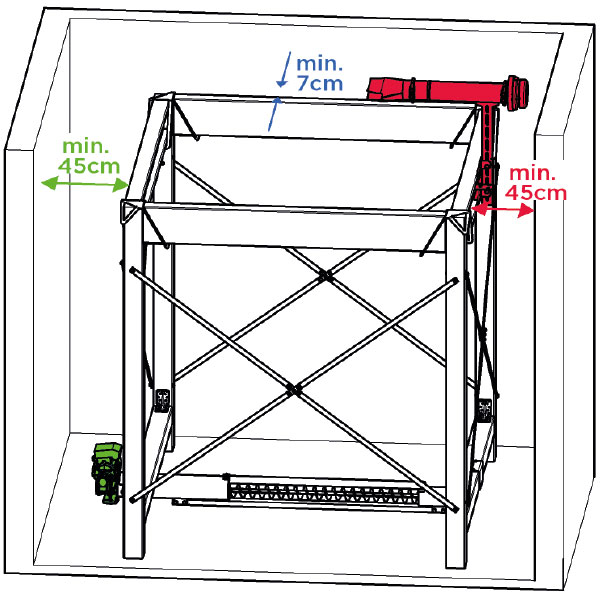

Minimum room size

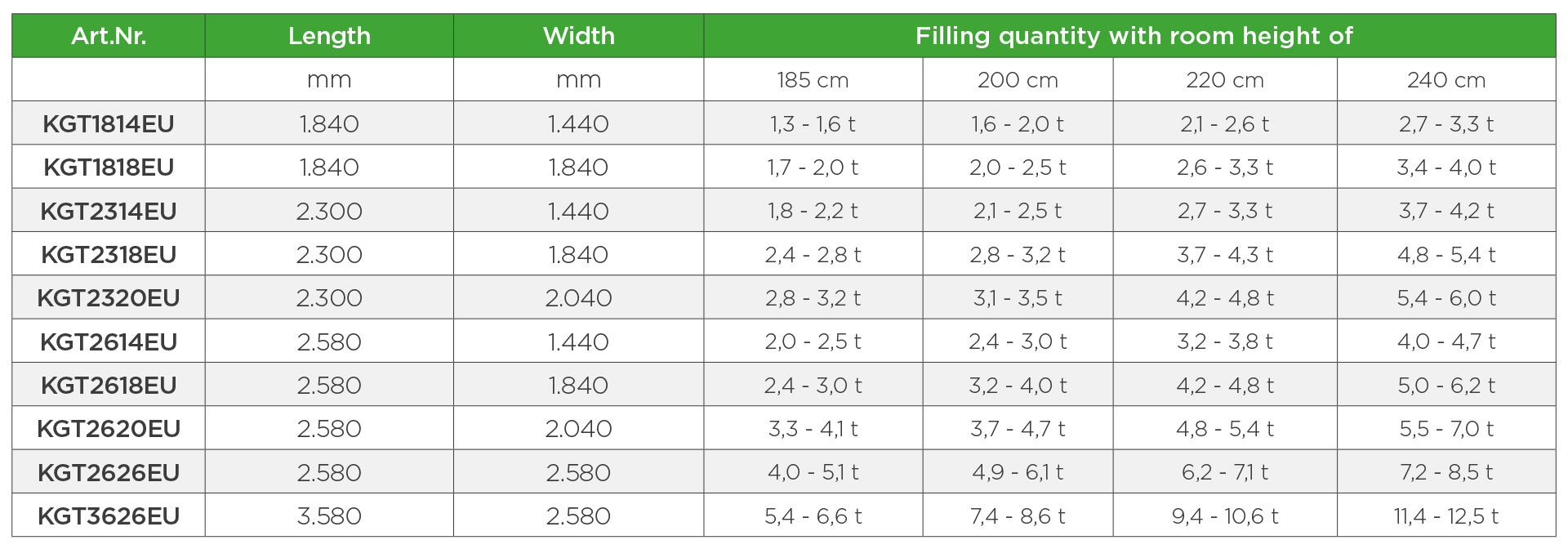

Flexilo Compact - filling quantities for room heights from 185 to 240 cm

1. Fabric tank with suction system

Fabric tank and heating system are up to 20m apart.

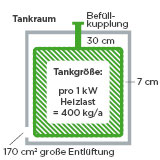

2. Size of the fabric tank

The tank size depends on the building heating load. Based on average heating habits, outcomes the following rule of thumb:

1kW heat load = 400kg of wood pellets a year.

For example:

Heating load 12 kW x 400 kg = 4800 kg ....... fabric tank KGT2618

Heating load 10 kW x 400 kg = 4000 kg ....... fabric tank S2622H

Heating load 7 kW x 400 kg = 2800 kg ....... fabric tank S190H

3. The location of the wood pellets tank room

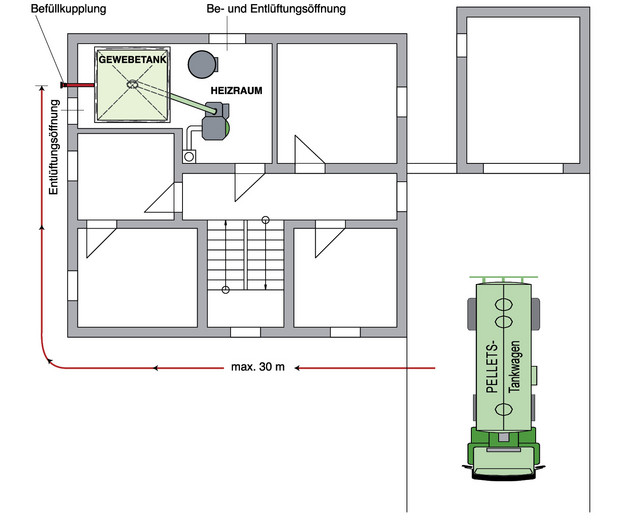

Pellets are delivered by tanker truck and are blown into the store room or the FlexiTank. The truck's pumping hose is max. 30 m length, so the FlexiTank (or rather the filler coupling) must be no more than 30m from the drive, parking space or road. If possible, the FlexiTank room should border at least one exterior wall, since the filler coupling must be accessible from the outside. Where this is not possible, ventilation and filling pipes must be routed to a filler coupling on the outside of the building. (Attention - in some countries fire regulations must be observed).

Size of the storage room

Layout:

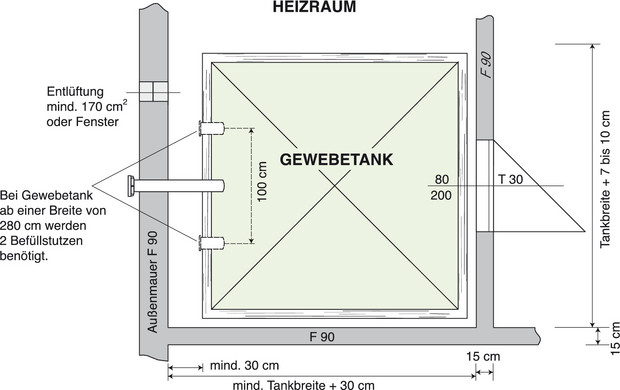

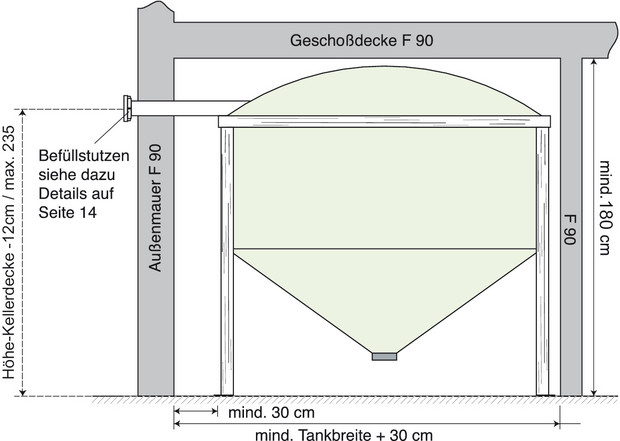

The room housing the Flexilo must be at least 7 - 10 cm wider than the tank itself.

For example: The S190 tank has a width of 197 cm, requiring a minimum room dimension of 205 cm on three sides, on the fourth side with the filler nozzle there must be 30cm additional clearance.

For example:

The FleXILO S190 requires a minimum room length of 205 cm + 30 cm = 235 cm on the "filler side".

Room height: The minimum room height is 215 cm.

Electrical requirements

The system is pre-wired ready to plug. In the boiler room a light outlet (230 volts) is required.

External emergency stop switch:

An emergency stop switch must be installed outside the boiler room, near the boiler room door.

4. Fitments of the tank and heating room

Perimeter walls:

The surrounding walls and the ceiling of the pellet storage room and the boiler room should correspond to fire resistance class F 90.

Doors:

As with all other heating systems, the boiler room and the storage room doors must be fired proof (at least T 30). They must open outwards and fitted with a seal.

Filling system:

Where a FleXILO is installed in a room, there must be adequate ventilation (window or similar with a minimum area of 170 cm²) to allow air to escape when the tank is being filled.

Fire protection:

Further information on fire regulations is available from your local OkoFEN specialist

Humidity:

The normal humidity of cellar walls is not a problem. However, the FleXILO must not touch wet walls. In the case of an outdoor installation, the FleXILO must be protected against rain and UV radiation. To avoid the pellets swelling,

it is imperative that water does not penetrate the tank.

5. Assembly video: The construction of the Flexilo Compact is as easy as this

We show you how easy it is to assemble our space-saving fabric tanks.