myEnergy365

pellets, solar and stirling engine generator

Generate electricity & heat from pellets & solar yourself all year round

Make your desire for independence a reality

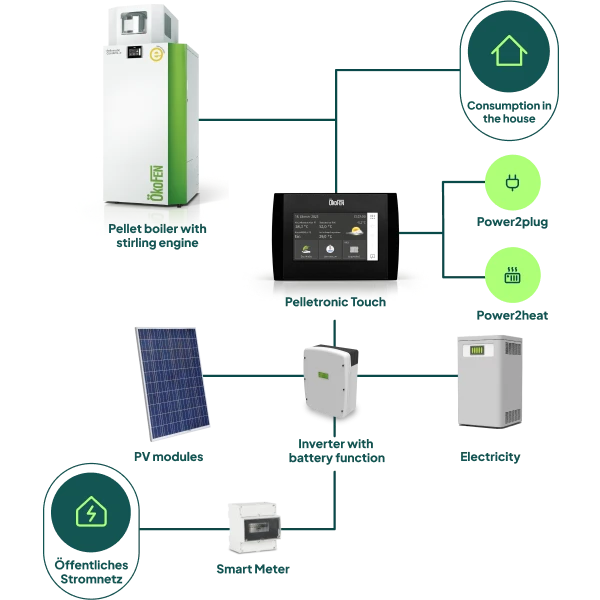

myEnergy365 from ÖkoFEN is the answer to the question of how to generate electricity and heat independently and ecologically in your own home.

The holistic approach, which intelligently combines the latest technologies, opens up the unique opportunity for the first time to utilise totally ecological heat and self-generated electricity from pellets and the sun in a detached house. The concept is modularly structured. The innovation is offered as a complete system, although it can also be implemented step by step. An existing photovoltaic system can be integrated and the Stirling engine for electricity generation retrofitted at a later date.

This allows consumers to become gradually more independent in the manner best suited to their requirements and budget.

The Pellematic Condens

The core component of the power-producing pellet heating system is the Pellematic Condens, one of the most efficient pellet boilers with condensing technology.

Pioneering Condens condensing technology helps achieve an efficiency of 107.3%* combined with minimum emissions. Thanks to its compact design, the pellet boiler also fits into the smallest of boiler rooms and leads the way in terms of efficiency and space savings.

The pellet boiler can be equipped with a Stirling engine for electricity generation either straight away or at a later date. The Pellematic Condens is supplied with an eReady pack for the retrofitting option. Prepared interfaces on the controller and hydraulics enable subsequent installation of the Stirling engine, thereby providing the first step towards energy independence.

Step-by-step towards energy freedom

Intelligent regulation

The operation of the Stirling engine depends on the weather and the production of the PV system. If a lot of sun is available, the heating system is supplied from the buffer storage and the PV system charges the battery.

In addition, the photovoltaic system stores your unrequired electricity production in the energy storage. On days without sun the Stirling engine runs and supplies the building with heat and electricity.

The Pellematic Condens_e

The core component of myEnergy365 is the Pellematic Condens_e, a pellet boiler that also generates electricity. In addition, the heating system is supplemented with a Stirling engine. In contrast to petrol and diesel engines, where combustion is internal, heat is supplied to the Stirling engine from the outside.

This engine filled with helium is located above the pellet combustion zone. The energy is produced by two different temperature zones that heat and cool the working gas. Expansion of the gas creates a pressure wave that moves a piston and generates electricity.

The Stirling engine is operated by the heat from the pellet boiler, with very little increase in pellet demand. This enables cost-effective electricity generation. A short response time makes the electrical output available very quickly. Another benefit is that the engine is maintenance-free.

Menue

Menue