Pellematic Condens

Pellet condensing boiler

The Pellematic Condens condensing boiler sets new standards. With its pioneering Condens technology, the boiler makes it possible to use condensing technology in any heat distribution system: The innovative pellet boiler can also be installed flexibly in the event of higher return temperatures, which is often the case in modernisation projects.

Highlights of the Pellematic Condens

The benefits of the Pellematic Condens at a glance

The technical refinements

Simple access for maintenance and cleaning

Pellet feed by vacuum suction system

Fully automatic heat exchanger cleaning carried out mechanically and with water

Stainless steel condensing heat exchanger with up to 15 % more efficiency

Output and combustion control optimised by combustion chamber sensor (automatic fuel adaptation)

Hopper 50 litres / 32 kg

Proven burn-back protection

Negative draft measurement

Multi-segment burner plate

Electronic ignition with glow rod (250 W output only)

Comfort ash box 13.9 litres / 7.5 kg with compaction

Automatic de-ashing system

Touch Display

eReady Paket (optional)

The unique combustion technology developed by ÖkoFEN enables highly efficient combustion with low emissions, thanks to its three main components: multi-segment burner plate, combustion chamber sensor and negative draft control. Condens condensing technology has revolutionised the practicability of pellet condensing technology. As well as being suitable for high-temperature systems with radiators, there is no need for a buffer cylinder either.

- Quick and easy installation: Hardly any dismantling work is required for transporting the boiler into the boiler room.

- Optimum combustion: Tried-and-tested combustion technology is employed in all ÖkoFEN pellet boilers.

- Condensing + conventional: The new Condens condensing technology allows the Pellematic Condens to be operated in any heating system.

The technical refinements

Simple access for maintenance and cleaning

Pellet feed by vacuum suction system

(mechanisch und mit Wasser)

Pellet feed by vacuum suction system

Fully automatic heat exchanger cleaning carried out mechanically and with water

für rasches Erreichen der optimalen Verbrennungstemperatur – weniger Stillstandsverlust

Fully automatic heat exchanger cleaning carried out mechanically and with water

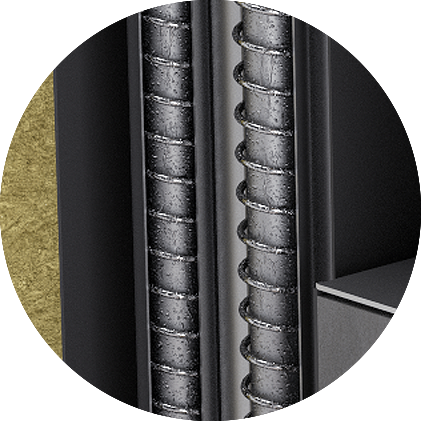

Stainless steel condensing heat exchanger with up to 15 % more efficiency

auf Feuerfestbeton

Hopper 50 litres / 32 kg

nur 250 Watt Leistung

Proven burn-back protection

Vakuumsaugsystem

Negative draft measurement

für einfache Bedienung

Multi-segment burner plate

50 Liter / 32 kg

Comfort ash box 13.9 litres / 7.5 kg with compaction

Electronic ignition with glow rod (250 W output only)

Automatic de-ashing system

Automatische Ascheaustragung

Komfort-Aschebox

optimiert für lange Entleerintervalle, automatische Benachrichtigung, wenn die Box voll ist.The unique combustion technology developed by ÖkoFEN enables highly efficient combustion with low emissions, thanks to its three main components: multi-segment burner plate, combustion chamber sensor and negative draft control. Condens condensing technology has revolutionised the practicability of pellet condensing technology. As well as being suitable for high-temperature systems with radiators, there is no need for a buffer cylinder either.

- Quick and easy installation: Hardly any dismantling work is required for transporting the boiler into the boiler room.

- Optimum combustion: Tried-and-tested combustion technology is employed in all ÖkoFEN pellet boilers.

- Condensing + conventional: The new Condens condensing technology allows the Pellematic Condens to be operated in any heating system.